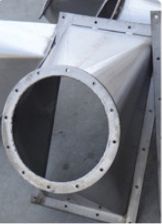

2000w ephathwa ngesandla laser welder

I-PARAMETER YOBUGCISA

Intshayelelo

Ngophuhliso oluqhubekayo lweshishini leemoto, iimfuno zemveliso yemoto esebenzayo kunye nomgangatho nazo ziyanda ngokuthe ngcembe. Kwinkqubo yokuvelisa iimoto, ukuwelda umzimba linyathelo elibalulekileyo, kwaye oomatshini bokuwelda ngesandla badlala indima ebalulekileyo kule nkqubo. Eli nqaku liza kunika intshayelelo ecacileyo yokusetyenziswa koomatshini be-welding ephathwayo kwi-welding yomzimba.

Intshayelelo kumatshini wokuwelda ngesandla

Oomatshini bokuwelda ngesandla basebenza kakuhle kwaye bebhetyebhetye izixhobo zokuwelda ezisetyenziswa ngokubanzi kumashishini ahlukeneyo afana nokuvelisa iimoto, ukugcinwa koomatshini kunye nokwakha. Ineengenelo zokuphatheka ngokulula, ukusebenza ngokulula, kunye nokugcinwa lula, ngenxa yoko idlala indima engenakuthathelwa indawo kwi-welding yomzimba.

Ukusetyenziswa komatshini wokuwelda obambe ngesandla kwi-welding body welding

Ukuphucula ukusebenza kakuhle:Ukusebenzisa umatshini wokuwelda obambe ngesandla ukuwelda umzimba kunokuphucula kakhulu ukusebenza kakuhle. Ukusebenza koomatshini bokuwelda ngesandla kulula, kwaye abasebenzi abanezakhono banokwenza imisebenzi ye-welding emininzi ngaxeshanye, banciphise kakhulu umjikelo wemveliso.

Umgangatho ozinzile:Umatshini we-welding obambe ngesandla unomgangatho ozinzileyo we-welding kwaye unokuhlangabezana neemfuno ezahlukeneyo zenkqubo engqongqo. Ngolawulo oluchanekileyo lwangoku kunye ne-voltage, ukuzinza kunye nokuthembeka kwamanqaku e-welding kunokuqinisekiswa.

Ukuba bhetyebhetye olomeleleyo:Umatshini we-welding we-handheld kulula ukuwuthwala kwaye unokusetyenziswa kwiindawo ezahlukeneyo zokusebenza. Oku kuvumela uhlengahlengiso oluguquguqukayo lwezikhundla ze-welding kunye nee-engile ngokweemfuno zangempela ngexesha lenkqubo ye-welding yomzimba, ukulungelelanisa kwiimfuno ezahlukeneyo ze-welding.

Ukunciphisa iindleko:Xa kuthelekiswa noomatshini bokuwelda bendawo, oomatshini bokuwelda ngesandla baneendleko eziphantsi zokufunyanwa kunye nokugcinwa kwazo. Okwangoku, ngenxa yokusebenza kwayo kakuhle kwe-welding, inokunciphisa umsebenzi kunye nexesha labasebenzi, ngaloo ndlela inciphisa iindleko zabasebenzi.

Ukuqukumbela

Isishwankathelo, oomatshini be-welding ababambe ngesandla badlala indima ebalulekileyo kwi-welding yomzimba. Iimpawu zayo ezisebenzayo, eziguquguqukayo, kunye nezizinzileyo zinika inzuzo ebalulekileyo ekuphuculeni ukusebenza kwemveliso, ukuqinisekisa umgangatho wemveliso, kunye nokunciphisa iindleko zemveliso. Ngophuhliso oluqhubekayo lwetekhnoloji, amathuba okusetyenziswa koomatshini bokuwelda ngesandla aya kuba banzi.

ISICELO

isetyenziswa kakhulu kumashishini aqhelekileyo

Isetyenziswa kakhulu kwimpahla yasekhitshini, umnyango kunye nefestile yokugada, i-elevator, intsimbi engatyiwa, ibhodi yehardware. Izixhobo, izipho zobugcisa, iimoto, i-aerospace kunye namanye amashishini

Guardrail

Ikhitshi, igumbi lokuhlambela kunye neempahla

Ishishini lentengiso

Imveliso yensimbi engenasici

Ishishini lezahlulo zemoto

Indawo yokubeka izibane

Ukwakhiwa koomatshini

I-PARAMETER YOBUGCISA

| LASER AMANDLA | 1000W | 1500W | 2000W |

| Ubunzulu obunyibilikayo (intsimbi engenasici, 1m/min) | 2.68mm | 3.59mm | 4.57mm |

| Ubunzulu bokunyibilika (intsimbi yekhabhoni, 1m/min) | 2.06mm | 2.77mm | 3.59mm |

| Ubunzulu bokunyibilika (ialloyi yealuminiyam, 1m/min) | 2mm | 3mm | 4mm |

| Ukutyisa ucingo oluzenzekelayo | φ0.8-1.2 i-welding wire | φI-0.8-1.6 i-welding wire | φ0.8-1.2 i-welding wire |

| Ukutya umbane | ≤3kw | ≤4.5kw | ≤6kw |

| Indlela yokupholisa | ukupholisa amanzi | ukupholisa amanzi | ukupholisa amanzi |

| Imfuno yamandla | 220v | 220v okanye 380v | 380v |

| Ukhuseleko lweArgon okanye initrogen (umthengi ngokwakhe) | 20 L/min | 20 L/min | 20 L/min |

| Ubungakanani besixhobo | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Ubunzima bezixhobo | ≈150kg | ≈170kg | ≈185kg |

Ukupakisha kunye nokuThumela

Lo matshini wawuza kupakishwa kwikhreyithi yomthi eqinileyo yokuthunyelwa ngenqanawa kumazwe ngamazwe, ilungele ukuthuthwa elwandle, emoyeni nakwindlela ekhawulezayo.