3000w laser welder

I-PARAMETER YOBUGCISA

| LASER AMANDLA | 1000W | 1500W | 2000W |

| Ubunzulu obunyibilikayo (intsimbi engenasici, 1m/min) | 2.68mm | 3.59mm | 4.57mm |

| Ubunzulu bokunyibilika (intsimbi yekhabhoni, 1m/min) | 2.06mm | 2.77mm | 3.59mm |

| Ubunzulu bokunyibilika (ialloyi yealuminiyam, 1m/min) | 2mm | 3mm | 4mm |

| Ukutyisa ucingo oluzenzekelayo | φ0.8-1.2 i-welding wire | φI-0.8-1.6 i-welding wire | φ0.8-1.2 i-welding wire |

| Ukutya umbane | ≤3kw | ≤4.5kw | ≤6kw |

| Indlela yokupholisa | ukupholisa amanzi | ukupholisa amanzi | ukupholisa amanzi |

| Imfuno yamandla | 220v | 220v okanye 380v | 380v |

| Ukhuseleko lweArgon okanye initrogen (umthengi ngokwakhe) | 20 L/min | 20 L/min | 20 L/min |

| Ubungakanani besixhobo | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Ubunzima bezixhobo | ≈150kg | ≈170kg | ≈185kg |

Ukusetyenziswa komatshini we-laser welding ephathwayo kwishishini le-aerospace

Intshayelelo

Kwishishini le-aerospace, iinkqubo zokuwelda ezikumgangatho ophezulu zibalulekile ekuqinisekiseni ukhuseleko nokusebenza kwenqwelo-moya. Kwiminyaka yakutshanje, oomatshini bokuwelda i-laser baye bafumana ukuthandwa kwishishini ngenxa yeenzuzo zabo ezizodwa. Eli nqaku liza kubonelela ngentshayelelo ecacileyo yokusetyenziswa koomatshini be-laser welding ephathwayo kwishishini le-aerospace.

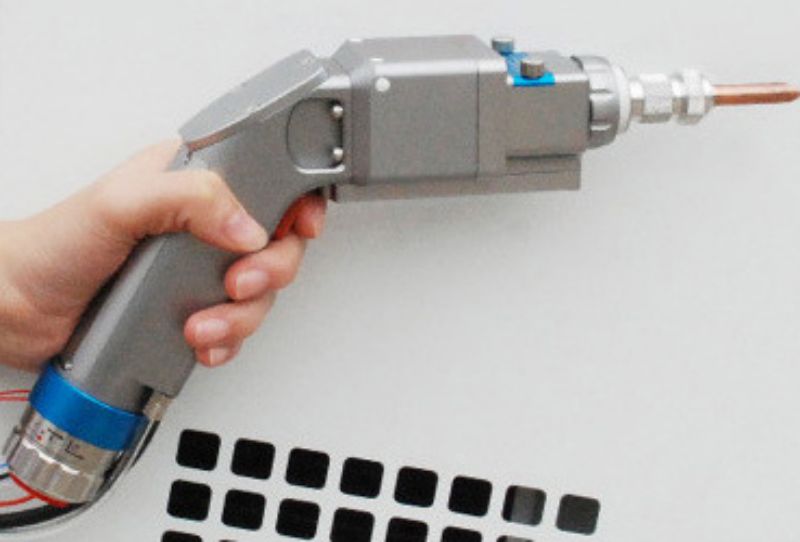

Intshayelelo kumatshini wokuwelda weLaser ophathwa ngesandla

Umatshini we-laser welding we-handheld yi-laser welding ye-laser ye-laser esebenzisa umthombo ophezulu we-laser wamandla, othunyelwa ngee-fiber optical, kwaye ujolise ngokuchanekileyo kwaye ulungelelaniswe yinkqubo yokulawula ephezulu. Umatshini we-laser welding we-handheld unenzuzo yokusebenza okulula, ukuguquguquka okuqinileyo, isantya esikhawulezayo sokudibanisa, kunye nomgangatho ophezulu we-welding.

Isicelo kwishishini le-aerospace

Umgangatho ophezulu wokuwelda:Umatshini we-laser welding welding unokufezekisa injongo echanekileyo kunye nohlengahlengiso, ngaloo ndlela uqinisekisa umgangatho kunye nokuchaneka kwe-welding. Kwishishini le-aerospace, ukulawulwa komgangatho we-welding kubaluleke kakhulu, kwaye ukusetyenziswa kwe-handheld laser welding machine kunokuphucula kakhulu umgangatho we-welding.

Ukusebenza kakuhle:Umatshini we-laser welding we-handheld unokugqiba ukusebenza kwe-welding ephezulu ngexesha elifutshane, ukuphucula kakhulu ukusebenza kwemveliso. Oku kubaluleke kakhulu kwishishini le-aerospace, njengoko kufuna ukusetyenzwa kwenani elikhulu lamalungu kunye namacandelo, kwaye iinkqubo ezisebenzayo zemveliso zibalulekile ekuqinisekiseni umgangatho kunye nenkqubela phambili yokwenziwa kweenqwelomoya.

Ukuba bhetyebhetye:Oomatshini bokuwelda bezandla be-laser banokuguquguquka okuphezulu kwaye banokujongana neemfuno ezahlukeneyo zokuwelda. Nokuba kukuwelding amabala, i-butt welding, okanye i-fillet welding, i-handheld laser welding machines inokusingatha ngokulula. Olu bhetyebhetye lunika inzuzo enkulu ekuphatheni amacandelo eemilo ezahlukeneyo kunye nobukhulu.

Ukuziqhelanisa:Umatshini we-laser welding we-handheld unokulungelelanisa kwizinto ezahlukeneyo zamacandelo, kuquka isinyithi, i-non-metal, njl. Oku kulungelelaniswa kwenza ukuba idlale indima ebalulekileyo ekuphatheni iintlobo ezahlukeneyo zeenqwelo-moya.

Ukulungelelana kokusingqongileyo:Umatshini we-laser welding we-handheld awuvelisi izinto ezinobungozi ngexesha lenkqubo ye-welding kwaye ihlangabezana neemfuno zokusingqongileyo. Kwishishini le-aerospace, ubuhlobo bendalo bubaluleke kakhulu, ngoko ke ukusetyenziswa koomatshini be-laser welding welding kunokunceda ukunciphisa impembelelo kwindalo.

Ukuqukumbela

Iingenelo zoomatshini bokuwelda belaser babenza basebenze ngokubanzi kwishishini le-aerospace. Ayinakuphucula kuphela ukusebenza kakuhle kwemveliso, kodwa ikwazi ukumelana neemfuno ezahlukeneyo ze-welding. Kwangaxeshanye, ubuhlobo bayo bokusingqongileyo kunye neempawu zokonga abasebenzi nazo ziyenza ibe lolona khetho lufanelekileyo kwishishini le-aerospace. Ngophuhliso oluqhubekayo lwetheknoloji, ukusebenza kunye nemisebenzi ye-handheld laser welding machines nayo iya kuphuculwa ngakumbi kwaye iphuculwe, kwaye izicelo zabo kwishishini le-aerospace nazo ziya kuba zibanzi kwaye zinzulu.

Ukuphuculwa komgangatho weWelding Iindlela zokuwelda ezintandathu

Iyakwazi ukugqiba iimfuno ze-welding ezingenakuzaliswa ngabashicileli abaqhelekileyo, kwaye i-weld iqinile kwaye inhle,Akukho slag welding, akukho lula deformation, emnyama

Ukuwelda indawo:indawo encinci, amandla anamandla, imowudi ye-welding ingasetyenziswa xa izinto zineemfuno zokungena kwe-welding;

Umgca othe tye:ububanzi bunokulungelelaniswa, i-material inokungena, ekudibaniseni i-welding, i-wire feeding welding, i-Positive fillet welding inokusebenzisa imowudi ye-welding;

"O" uhlobo:Idayimitha ehlengahlengiswayo, ukuhanjiswa okufanayo koxinzelelo lwamandla; I-frequency ephezulu xa i-welding sheet "O" inokusetyenziswa;

Kabini "O":Idayamitha ehlengahlengiswayo, ukunciphisa indawo yokukhanya, ilungele ukuwelda kwii-engile ezahlukeneyo;

Unxantathu:Ububanzi bunokulungiswa ukunciphisa indawo yokukhanya ngelixa amandla emiphetho emithathu afanayo. Umbindi kunye namacala omabini epleyiti ashushu ngokupheleleyo;

"8" igama:qhubeka nokwandisa indawo yokukhanya kwisiseko sonxantathu, ukwenzela ukuba i-plate iqhume ngokuphindaphindiweyo, inkulu.

Ipateni "8" ingasetyenziselwa ukudibanisa ububanzi.

Ukupakisha kunye nokuThumela

Lo matshini wawuza kupakishwa kwikhreyithi yomthi eqinileyo yokuthunyelwa ngenqanawa kumazwe ngamazwe, ilungele ukuthuthwa elwandle, emoyeni nakwindlela ekhawulezayo.