Umatshini wokuwelda weLaser ophathwa ngesandla wokulungisa uMngundo

Intshayelelo yeMveliso

Intshayelelo

Ngophuhliso oluqhubekayo lobuchwephesha, ukusetyenziswa komatshini we-laser welding welding kushishino lokwakha kuye kwaba ngumkhwa. Le ndlela intsha yokuwelda izise utshintsho kwishishini lokwakha ngenxa yokusebenza kwayo okuphezulu, ukuchaneka, kunye nokusebenza ngokulula. Eli nqaku liza kubonelela ngentshayelelo eneenkcukacha kwimigaqo, iinzuzo, kunye nokusetyenziswa koomatshini bokuwelda belaser kushishino lokwakha.

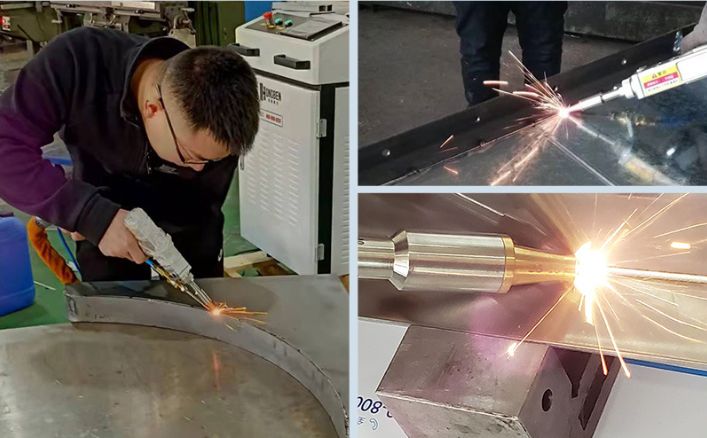

Isishwankathelo somatshini wokuwelda weLaser ophathwa ngesandla

Umatshini we-laser welding we-handheld sisixhobo esisebenzayo kunye nesichanekileyo se-welding esisebenzisa i-laser njengomthombo wokushisa kwaye uhambisa ngeefiber ze-optical ukuphumeza umgama omde kunye nokusebenza kwe-welding ephezulu. Xa kuthelekiswa ne-arc welding yemveli, i-laser welding inoxinano lwamandla aphezulu, isantya sokupholisa ngokukhawuleza, kunye nokungena nzulu, okunokufikelela kwi-welding esebenzayo kunye nekumgangatho ophezulu.

Iinkcukacha zoomatshini

Iingenelo koomatshini bokuwelda belaser ngesandla

Ukusebenza kakuhle:Ukusebenza kwe-laser welding kuphezulu kakhulu kunoko kwe-arc welding yendabuko, enokunciphisa kakhulu ixesha le-welding kunye nokunciphisa iindleko zabasebenzi.

Ukuchaneka:Ukuwelda kweLaser kunokufezekisa ukuwelda okuchanekileyo, okwenza kube lula ngakumbi ukuwelda iimilo ezintsonkothileyo kunye nezakhiwo.

Kulula ukusebenza:Umatshini we-laser welding welding kulula ukuyisebenzisa kwaye unokuqhutywa ngabasebenzi abafumene uqeqesho olulula.

Ukuba bhetyebhetye:Uyilo oluphathwa ngesandla luvumela umatshini we-laser welding ukuba asebenze ngokuguquguqukayo nakwindawo ezisikelwe umda.

Ukulungelelana kokusingqongileyo:Inkqubo yokuwelda i-laser ayinamsi, ayinavumba, kwaye ayinangxolo, inefuthe elincinci kokusingqongileyo.

Ukusetyenziswa koomatshini bokuwelda belaser kushishino lokwakha

Ukuwelda kwemivalo yentsimbi:Kwishishini lokwakha, i-welding yentsimbi yentsimbi yinkqubo ebaluleke kakhulu. Umatshini we-laser welding we-handheld unokugqiba ngokukhawuleza kwaye ngokuchanekileyo ukugqiba i-docking kunye nokugqithisa imivalo yentsimbi, ukuphucula ukusebenza kakuhle kokwakhiwa.

Ukuwelda kwesakhiwo sentsimbi:Ulwakhiwo lwensimbi lusetyenziswa ngokuqhelekileyo kwisakhiwo sezakhiwo zanamhlanje, kwaye umgangatho we-welding uchaphazela ngokuthe ngqo ukhuseleko lwesakhiwo. Oomatshini be-laser welding ephathwayo banokufikelela kwi-welding ephezulu, ukuphucula umgangatho kunye nokuzinza kwezakhiwo zetsimbi.

Ukuwelda udonga lomkhusane weglasi:Ukufakwa kweendonga zamakhethini eglasi kufuna iteknoloji ye-welding ephezulu. Umatshini we-laser welding we-handheld unokufikelela kwi-docking ephezulu kunye nokugqithisa, ukuphucula ukufakwa kakuhle kunye nokhuseleko lweendonga zamakhethini eglasi.

Ukuwelda kwemibhobho:Kwishishini lokwakha, ukuwelda kwemibhobho nako kuyikhonkco elibaluleke kakhulu. Oomatshini be-laser welding ephathwayo banokufikelela kwi-docking ephezulu kunye nokugqithisa, ukuphucula ukhuseleko kunye nokuzinza kwemibhobho.

Umhombiso wokuwelda:Isixa esikhulu somsebenzi we-welding siyafuneka ekuhombiseni, kwaye ukuguquguquka kunye nokuchaneka koomatshini be-laser welding ephathwayo benza umsebenzi wokuhlobisa usebenze ngakumbi kwaye uhle.

Ukuqukumbela

Ukuvela koomatshini be-laser welding welding kwazisa amathuba amatsha kunye nemingeni kushishino lokwakha. Ibe yindlela entsha nesebenzayo yokuwelda kushishino lokwakha ngenxa yokusebenza kwayo okuphezulu, ukuchaneka, kunye nokusebenza ngokulula. Ngenkqubela phambili eqhubekayo yethekhinoloji kunye nokwandiswa kweendawo zokufaka izicelo, ukusetyenziswa koomatshini be-laser welding ephathwayo kwishishini lokwakha kuya kuba kuninzi, kuzisa amathuba amaninzi okuphuhliswa koshishino lokwakha.

Isantya 3 ~ 10 amaxesha ngokukhawuleza kunewelding yemveli

Hkwayeibanjiwe LaserWeldingSuchamaCan Rnganye 120mm/s

Iinkcukacha zoomatshini

I-PARAMETER YOBUGCISA

| LASER AMANDLA | 1000W | 1500W | 2000W |

| Ubunzulu obunyibilikayo (intsimbi engenasici, 1m/min) | 2.68mm | 3.59mm | 4.57mm |

| Ubunzulu bokunyibilika (intsimbi yekhabhoni, 1m/min) | 2.06mm | 2.77mm | 3.59mm |

| Ubunzulu bokunyibilika (ialloyi yealuminiyam, 1m/min) | 2mm | 3mm | 4mm |

| Ukutyisa ucingo oluzenzekelayo | φ0.8-1.2 i-welding wire | φI-0.8-1.6 i-welding wire | φ0.8-1.2 i-welding wire |

| Ukutya umbane | ≤3kw | ≤4.5kw | ≤6kw |

| Indlela yokupholisa | ukupholisa amanzi | ukupholisa amanzi | ukupholisa amanzi |

| Imfuno yamandla | 220v | 220v okanye 380v | 380v |

| Ukhuseleko lweArgon okanye initrogen (umthengi ngokwakhe) | 20 L/min | 20 L/min | 20 L/min |

| Ubungakanani besixhobo | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Ubunzima bezixhobo | ≈150kg | ≈170kg | ≈185kg |

Ukupakisha kunye nokuThumela

Lo matshini wawuza kupakishwa kwikhreyithi yomthi eqinileyo yokuthunyelwa ngenqanawa kumazwe ngamazwe, ilungele ukuthuthwa elwandle, emoyeni nakwindlela ekhawulezayo.