Umatshini wokuWelding weLaser ophathwa ngesandla

Inkcazo

Umatshini wokuwelda we-Fiber laser we-Mini Type udibanisa iimpawu ezisisiseko zesixhobo esiphathwayo esine-ultra-portable kunye nokusebenza okungaguqukiyo.

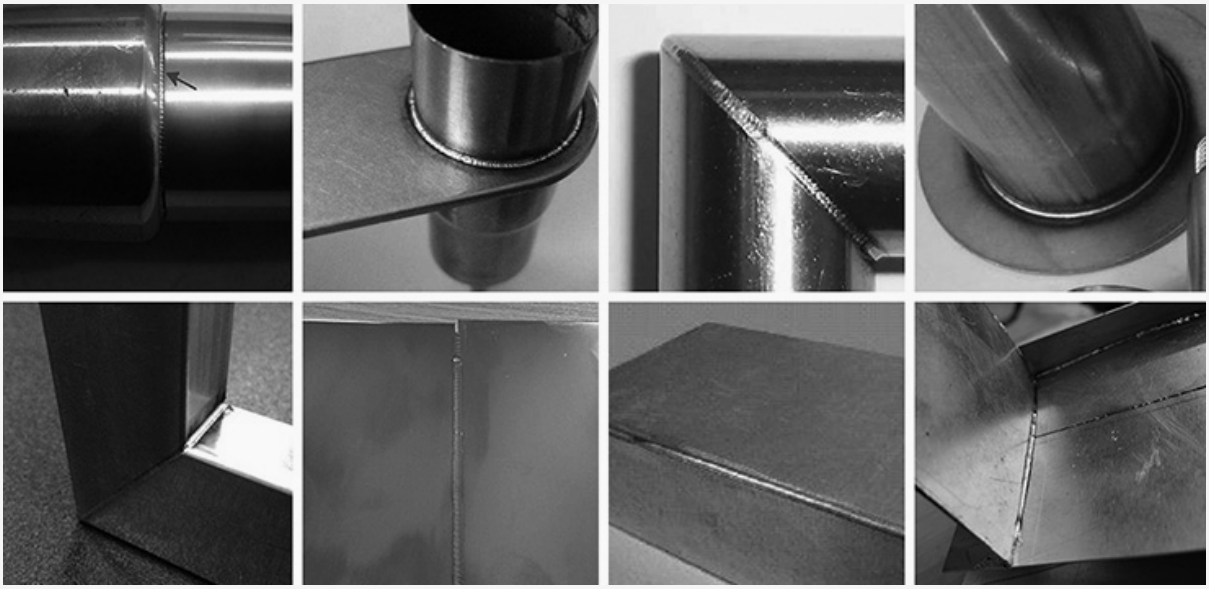

FTW-SL-1000/1500/2000 Mini ephathwayo umatshini laser welding wamkela isizukulwana yamva nje ifayibha laser kwaye ixhotyiswe OSPRI ephathwayo laser welding intloko, egcwalisa umsantsa welding ephathwayo kushishino lwezixhobo laser. Kunye neengenelo isantya welding fast kwaye akukho consumables, inokuthi indawo ngokugqibeleleyo argon zemveli Arc (TIG) welding, welding yombane kunye nezinye iinkqubo xa ukuwelda iipleyiti ezibhityileyo intsimbi stainless, iipleyiti zentsimbi, iipleyiti galvanized kunye nezinye izinto zentsimbi. I-laser ebanjwe ngesandla.

umatshini we-welding unokusetyenziswa ngokubanzi kwiinkqubo ze-welding eziyinkimbinkimbi kunye nezingaqhelekanga kwikhitshi yekhabhinethi kunye negumbi lokuhlambela, i-elevator ye-stair, i-shelf, i-oven, umnyango wensimbi engenasici kunye ne-window guardrail, ibhokisi yokuhambisa, indlu yensimbi engenasici kunye namanye amashishini.

IParameter yobuGcisa

| Umzekelo | FTW-SL-1000 | FTW-SL-1500 | FTW-SL-2000 |

| Amandla eLaser | 1000W | 1500W | 2000W |

| Umthombo weLaser | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE |

| Intloko yeLaser | OSPRI | OSPRI | OSPRI |

| Ubude beFiber Wire | 5/10 yeemitha | 5/10 yeemitha | 5/10 yeemitha |

| Laser Wavelength | 1070nm | 1070nm | 1070nm |

| Imo yokusebenza | Ukuqhubekeka/Lungisa | Ukuqhubekeka/Lungisa | Ukuqhubekeka/Lungisa |

| I-Chiller yamanzi | I-Hanli/S&A | I-Hanli/S&A | I-Hanli/S&A |

| Uluhlu loLungiso lweSpot | 0.1-3mm | 0.1-3mm | 0.1-3mm |

| Ukuphinda Ukuchaneka | ±0.01mm | ±0.01mm | ±0.01mm |

| Ubungakanani beKhabhinethi | 744*941*1030mm | 744*941*1030mm | 750*1260*1110mm |

| Ubunzima bomatshini | Malunga ne-200KG | Malunga ne-200KG | Malunga ne-220KG |

| I-Voltage | 110V/220V/380V | 110V/220V/380V | 110V/220V/380V |

Iingcebiso zoomatshini

1. Malunga noBubude beFiber Cable

Ngokuqhelekileyo ubude obuqhelekileyo yi-10m, ukuba unezinye iimfuno, sixhasa ukucutha okanye ukwandiswa.

2. Igesi encedisayo: i-nitrogen okanye i-argon

Ukuba i-welding surface effect iyadingeka ukuba ibe mhlophe kwaye ikhanye, i-nitrogen okanye i-argon iyadingeka.

Ukuba akukho mfuneko ye-welding surface, yongeza umoya ocinezelweyo we-Dryer, umoya ulungile.

3. Malunga ne-wire feeder

Lulungiselelo olusemgangathweni lomatshini, siya kuthumela kuwe kunye nomatshini wonke.

4. Iwaranti yomatshini

ngokwesiqhelo 2 iminyaka, sinazo professional emva intengiso iqela, 24 iiyure online.

Ukusetyenziswa komatshini

I-Fiber Laser welding machine ilungele ukuwelda igolide, isilivere, i-titanium, i-nickel, i-tin, ubhedu, i-aluminiyam kunye nezinye isinyithi kunye nezixhobo zazo ze-alloy. Inokufikelela kwi-welding echanekileyo efanayo phakathi kwesinyithi kunye neentsimbi ezingafaniyo. Isetyenziswe ngokubanzi kwi-aerospace, ukwakha iinqanawa kunye nezixhobo. Iimveliso zoomatshini kunye nezombane, iimoto kunye namanye amashishini.

Iinkcukacha zoomatshini

I-RAYCUS MAX SUNLITE IFayibha yeLaser Source Optional

Xa kuthelekiswa neemveliso ezifanayo, i-RAYCUS MAX SUNLITE I-Fiber laser Source inamandla aphezulu okuguqula i-photoelectric perfor-mance, i-stablebeam, kunye nekhono elinamandla lokuchasa.

Amandla e-laser akhethwayo asuka kwi-1000 ukuya kwi-2000 watts. Sine-R&D esebenzayo kunye neqela lemveliso, elikumgangatho ophezulu eTshayina. I-laser inokuguqulwa okuphezulu kwe-electro-optical.

I-OSPRI (QILIN) i-Fiber Laser Welding Head

1. Jinga intloko ye-welding

Inkqubo yokuba intloko yamagnetic yendabuko ayikwazi ukugqiba, intloko ye-welding ye-swing idinga kuphela ukusebenzisa i-70% yamandla, enokugcina iindleko ze-laser; Ukongeza, indlela ye-welding ye-swing yamkelwe, ububanzi bokudibanisa i-welding buyahlengahlengiswa, kwaye ukunyamezela impazamo ye-welding kunamandla, okwenza iintsilelo ezincinci ze-laser welding joint. Uluhlu lokunyamezelana kunye nobubanzi be-welding yeendawo ezicutshungulwayo zandiswa, kwaye isiphumo esihle sokwenza i-welding sifunyenwe.

2. 360 degree micro welding

Emva kokuba i-laser beam igxininisekile, inqaku linokubekwa ngokuchanekileyo kwaye lisetyenziswe kwiqela le-welding ye-workpieces encinci kunye ne-micro ukuphumeza imveliso yobuninzi.

3. Intloko ye-laser yokuwelda ephathwayo Imilomo

Xa sine-fiber handheld laser welder kwaye sitshintshe i-nozzle ye-welding nge-nozzle yokusika, sinokuyibiza ngokuba yi-handheld fiber laser welding kunye nomatshini wokusika. Ayililo igama elihle!

Ingathatha i-fiber optical kwi-fiber laser kwaye iyiqokelele kwindawo encinci ukuvelisa i-laser ephezulu ngenjongo yokusika. Nangona kunjalo, nceda uqaphele ukuba ayikwazi ukusika izinto ezityebileyo.

Umgangatho ophezulu we-Ospri Wobble Welding Head

1. I-welding edibeneyo iphuhliswe ngokuzimeleyo ithatha imo ye-welding ye-swing.

2. Ububanzi bendawo yokukhanya bunokulungiswa.

3. I-welding fault tolerance yomelele, eyenza ukungonakali kwe-laser encinci ye-welding spot, yandisa uluhlu lokunyamezela kunye nobubanzi be-weld yeendawo ezicutshungulwayo, kwaye ifumana ukubunjwa kwe-weld engcono.

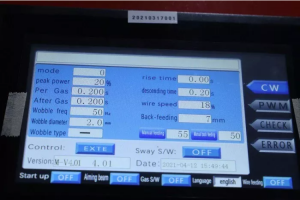

OSPRI Control System

Inkqubo yolawulo ye-OSPRI yenzelwe ngokukodwa ukukhuphisana nentloko yayo ye-OSPRI laser welding. Iza neentlobo ezimbalwa zemowudi, imodeli yeCW, imodeli ye-PWM imodeli yeArc.

Isikrini sokulawula ngokuthe ngqo kwidijithali sibeka iiparamitha ze-wire feeder.

Inkqubo ibeka iliso kwimo yokusebenza ngexesha lokwenyani, iliso kwaye iqokelele ubume bokusebenza kwelaser, chiller, kunye nebhodi yolawulo.

Ixhasa iinkqubo zesiTshayina, isiNgesi, isiKorea, isiJapan, isiRashiya, isiFrentshi, iSpanish, ulwimi lwakwaSirayeli.

I-HANLI Water Chiller YE-LASER WELDER (UKUKHETHA)

I-Hanli Water Chiller Iphuhliswe ngokukodwa izixhobo ze-fiber laser, isiphumo esihle sokupholisa. Ukusebenza okuzinzileyo nokuthembekileyo, izinga lokungaphumeleli eliphantsi, amandla asebenzayo.

I-Automatic Wire Feeder

Ulwakhiwo lokutya kweengcingo ezimbini lwenza ukuba ukutyiswa kweengcingo kube lula kwaye komelele ngaphandle kokugxumeka kocingo; Uyilo lwe-chassis oluvaliweyo, olunomqheba ophakanyiswayo kunye nevili lehlabathi jikelele; Umlawuli wokutyisa ucingo, isikrini se-LED sidlala isantya sangempela sokutya kweengcingo; Iqhosha lokulawula isantya esiphezulu esichanekileyo, kunye nokulawulwa kwesantya sokutya ngocingo.

1000W kunye 1500W inkxaso 0.8mm 1.0mm 1.2mm ucingo, 2000W inkxaso 0.8mm ukuba 1.6mm.

Ukuthumela ngocingo kunye nesantya sangasemva silungelelanisa ngephaneli yokubamba.

Ukuba umsantsa ezimbini weld metal ngaphezu 0.2mm ukuba kufuneka ucingo filler.

I-Advantage yeMveliso

UKUSHISA NGEFIBER LASER Vs. Ukuwelda kwe-TIG eqhelekileyo

IFIBER LASER UKUSHISA

Ukusebenza okulula, ukunciphisa kakhulu iindleko zabasebenzi.Imitha engathanga ngqo incinci. Isantya esikhawulezayo kunye nokusebenza kakuhle ngamaxesha e-3-8 ye-argon arc welding.Amandla agxininisiweyo kunye nempembelelo encinci ye-thermal deformation.I-welding seam ecocekileyo, i-pool etyhidiweyo enzulu, amandla aphezulu. Izinto ezibhityileyo kakhulu zinokudityaniswa, njengentsimbi ye-0.05mm.Zombini i-autogenous welding kunye ne-additive welding zilungile.

Ukuwelda kwe-TIG eqhelekileyo

Iimfuno zobuchwephesha nezobuchwephesha ziphezulu, nto leyo ekhokelela kwiindleko eziphezulu zabasebenzi. Umonakalo omkhulu kumzimba womntu. Icotha kwaye ingasebenzi kakuhle. Impembelelo thermal mkhulu, nto leyo ekhokelela deformation enkulu. I-welding seam irhabaxa kwaye ayiqhelekanga. Ifuna ukusila kunye nokupholisha. Awukwazi ukuwelda izixhobo ezibhityileyo kakhulu. I-Consumables welding wire iyafuneka. Kulula ukuwela.

I-Welding Material Parameterkwireferensi yakho, izixhobo ezahlukeneyo, iiparamitha zewelding ezahlukeneyo, zilinganiselwe licandelo, bonisa ngokuthe ngqo inxalenye.

Ukuba ufuna ukwazi ngakumbi malunga neparameter, nceda uqhagamshelane nathi ngokuthe ngqo, iiyure ze-24 kwi-intanethi.