Umatshini wokuWelding weLaser wezixhobo zonyango

Iimpawu zoomatshini:

Ukusetyenziswa kweLaser Welding Machine kuShishino lweSixhobo sezoNyango

Oomatshini bokuwelda beLaser, njengobuchwephesha bokuwelda obuphambili, sele isetyenziswa kakhulu kushishino lwezixhobo zonyango. Oku kulandelayo yintshayelelo eneenkcukacha malunga nokusetyenziswa koomatshini be-laser welding kushishino lwezixhobo zonyango.

Ukuwelda kwezixhobo zotyando

Oomatshini bokuwelda ngeLaser badlala indima ebalulekileyo ekwenzeni izixhobo zotyando. Izixhobo zokuhlinzwa kufuneka zibe nokuchaneka okuphezulu kunye nokuthembeka ukuqinisekisa ukhuseleko kunye nokusebenza ngexesha lotyando. Oomatshini bokuwelda i-Laser banokufikelela kwi-welding ephezulu echanekileyo, ukuqinisekisa umgangatho kunye nokuhambelana kwendawo nganye ye-welding, kunye nokuphepha iingxaki ezifana ne-deformation kunye neentanda ezibangelwa iindlela ze-welding zendabuko. Kwangaxeshanye, oomatshini bokuwelda i-laser banokufikelela kwi-welding yeentlobo ezahlukeneyo zezixhobo zotyando, ukuhlangabezana neemfuno zotyando olwahlukileyo.

Ukuwelda izixhobo zamazinyo

Ukwenziwa kwezixhobo zamazinyo kufuna ubugcisa obuchanekileyo kunye nezixhobo eziphezulu zokuqinisekisa ukhuseleko lwesigulane kunye neziphumo zonyango. Oomatshini be-laser welding banokufikelela kwi-high-precision welding yezixhobo zamazinyo, ukuphepha iingxaki ezifana ne-deformation kunye neempazamo ezibangelwa iindlela ze-welding zendabuko. Kwangaxeshanye, oomatshini bokuwelda i-laser banokufikelela kwi-welding yeentlobo ezahlukeneyo zezixhobo zamazinyo, ukuhlangabezana neemfuno zeentlobo ezahlukeneyo zonyango lwamazinyo.

Ukuwelda kwezityalo zamathambo

Ukufakelwa kwe-Orthopedic zixhobo zonyango ezisetyenziselwa ukunyanga izifo ezifana nokuphuka, ezifuna ukuthembeka okuphezulu kunye nokuzinza. Oomatshini be-laser welding banokufikelela kwi-welding ephezulu yezityalo ze-orthopedic, ukuphepha iingxaki ezifana ne-deformation kunye neentanda ezibangelwa iindlela ze-welding zendabuko. Ngelo xesha, umatshini we-laser welding unokufezekisa iintlobo ezahlukeneyo ze-orthopedic implant welding, ukuphucula umphumo wotyando kunye nomgangatho wobomi bezigulane.

I-Welding yezixhobo zonyango ezingenelelayo

Izixhobo zonyango ezingenelelayo zizixhobo zonyango ezichanekileyo ezifuna ukwenziwa nokulungiswa okuchanekileyo. Oomatshini be-laser welding banokufikelela kwi-welding ephezulu echanekileyo yezixhobo zonyango ezingenelelayo, ukuphepha iingxaki ezifana ne-deformation kunye neempazamo ezibangelwa iindlela ze-welding zendabuko. Kwangaxeshanye, oomatshini bokuwelda i-laser banokufikelela kwi-welding yeentlobo ezahlukeneyo zezixhobo zonyango ezingenelelayo, ukuphucula ukusebenza kotyando kunye nokhuseleko lwesigulane.

Ngamafutshane, oomatshini bokuwelda belaser baye basetyenziswa ngokubanzi kushishino lwezixhobo zonyango, bezisa utshintsho oluguquguqukayo ekwenzeni izixhobo zonyango. Ayiphuculi kuphela ukusebenza kakuhle kwemveliso kunye nokunciphisa iindleko zemveliso, kodwa iphucula umgangatho wemveliso kunye nokhuseleko. Ngenkqubela phambili eqhubekayo yeteknoloji kunye nokunyuka kwemfuno yezicelo kwixesha elizayo, amathuba okusetyenziswa koomatshini be-laser welding kushishino lwezixhobo zonyango luya kuba lubanzi ngakumbi.

Iinkcukacha zoomatshini

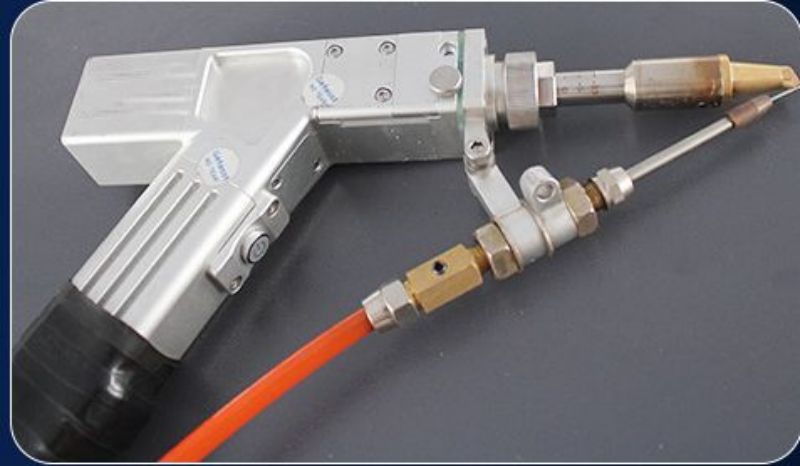

Intelligent welding joint

Isizukulwana sesine sentloko ye-welding ekrelekrele inobunzima be-0.8KG kuphela, ukusebenza kwexesha elide akukhathali, kwaye uyilo lomjikelo wamanzi kabini unesiphumo esihle sokupholisa kunye nokuzinza okuhle.

Iilensi zokukhusela kabini

Ubomi obude, ukukhusela ngokufanelekileyo isibuko sokugxila kunye nentloko ye-QBH, ukunciphisa ngokufanelekileyo umonakalo wezinye iindawo zentloko ye-welding ebangelwa ukusebenza okungafanelekanga xa i-lens yokukhusela yonakaliswa.

Iqhosha lentloko yethu ye-welding yesizukulwana sesine yamkela itekhnoloji yokhuseleko lokuthintela ngengozi ukunqanda ukuphuma kwelaser okubangelwa kukuchukumisa iqhosha ngempazamo, elikhuseleke ngakumbi ukulisebenzisa.

Ucingo lombhobho wokutya

Umbhobho wesondlo wamkela uyilo oluchasene ne-bias kwinkqubo yokusetyenziswa ukunqanda ngokufanelekileyo umgangatho we-welding obangelwa ukutenxa kocingo lwe-welding.

Inkqubo yokulawula

Inguqulo ye-V5.2 yenkqubo yokulawula inokukhawuleza ukulungelelanisa iiparitha ezahlukeneyo zomatshini kunye nesimo somatshini sinokubonakala ngokucacileyo. Iiparamitha zenkqubo zinokugcina iiseti ezininzi zedatha ukuze zisetyenziswe lula kwaye zixhase ukutshintsha kweelwimi ezininzi

Ifayibha laser

Iibrendi ezininzi zefiber optic excitation

Isixhobo se-Optical, kubathengi ukuba bakhethe ngokukhululekileyo, nabo banokukhetha uphawu lwelaser olungenisiweyo.

Umxhasi wocingo

Indlela i-welding spot ephuma ngayo ibaluleke kakhulu kwi-feeder yocingo, i-fire feeder yenkampani yethu isebenzisa i-motor stepper ukuqhuba eyomeleleyo kwaye inamandla, ukunqanda ukutya kocingo. Iingxaki ezifana nokutya okungazinzanga ngocingo

I-PARAMETER YOBUGCISA

| Uphawu lwemveliso | HRC Laser | Igama lemveliso | Umatshini wokuwelda welaser ophathwa ngesandla |

| Indlela yokuwelda | Ukuwelda ngesandla (okuzenzekelayo) | ubunzulu be-welding | 0.8-10MM |

| Welding ububanzi | 0.5-5MM | Tonceda ufumane | ukukhanya okubomvu |

| Irhasi yokuwelda | IArgon Nitrogen ixinzelelwe umoya (akukho manzi) | isantya welding | 1-120MM/S |

| Ubude bosinga lwe-Optical | 10M | Ubunzima bepleyiti ye-welding | 0.3-10MM |

| Imo yokupholisa | Ukupholisa ngamanzi | imfuno yamandla | 220V/380V 50/60Hz |

| Ubungakanani besixhobo | 1200*650*1100MM | Ubunzima bezixhobo | 160-220KG |

| Ifom ye-weld | ukuwelda ngeempundu;i-lap welding;i-rivet welding;welding roll; T ukuwelda;ukuwelda ngaphezulu,;welding edge,;njl | ||

| Izinto zokuwelda | Intsimbi engatyiwayo, intsimbi, intsimbi yekhabhoni, ialuminiyam, ingxubevange yealuminiyam, ubhedu, ishidi elenziwe ngesinyithi | ||

UMBONISO OMZEKELO

Ukupakisha kunye nokuThumela

Lo matshini wawuza kupakishwa kwikhreyithi yomthi eqinileyo yokuthunyelwa ngenqanawa kumazwe ngamazwe, ilungele ukuthuthwa elwandle, emoyeni nakwindlela ekhawulezayo.